Summit Engineering Machining & Fabrication

High quality machined, lasered and fabricated products, delivered on time, to your specifications

Sectors we service

At the forefront of engineering excellence our customers include major yellow goods manufacturers, heavy duty agriculture equipment suppliers & power generators.

Earth Moving

We fabricate heavy duty components and spare parts to major Yellow Goods manufacturers including but not limited to buckets, bonnets, battery boxes, linkage fulcrums, cabs and stabilizer legs.

Construction

We manufacture machined parts for backhoe loaders, diggers and excavators including but not limited to buckets, wheel accessories, pivot links, trailer hitches, stabilizers and forks.

Agriculture

We provide seed drilling parts, wheel hubs, couplings, links and robust moving parts to meet the demands of the Agricultural Sector.

Power & Rail

We supply specialist engineered components and parts to the power generation, transmission, distribution and transport sectors.

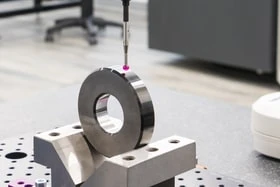

Precision Engineering

We are capable to manufacture to the minimum permissible customer set dimensional tolerances, and via our quality dept advanced measuring equipment we are capable to meet and certify to the most stringent ISO standards.

Design, Assembly & Bespoke Engineering Parts to complement your business

We are certified to ISO 9001:2015 and have been certified by Leicester University & ERDF to have achieved Gold Standard for the Social Impact Ambassadors Sustainability Audit.

Summit Group has achieved gold for the United Nations Sustainability Development Goals including the reduction of our CO2 emissions by 45% by 2025.

All our personnel levels of capability are constantly re-assessed and provided training to ensure our high standards are maintained.

- Delivering Parts Since

- 1955

- Skilled Employees

- 75+

- Production Space

- >6000m2

- Steel Tonnage Per Annum

- 2300

Key Customer Accounts

A showcase of our deliverables for one of our key customers

Yellow Goods

This sector has been the mainstay of our business for well over 30 years now. We have built up and maintained a relationship based on trust and understanding with two of the main market leaders, and have continuously supplied products to them on a weekly basis throughout this period. We understand the industries stringent and demanding standards, and with this level of experience and expertise we guarantee we can add value to any customer.

- High Volume

- In December 2023 we shipped over 25,000 individual components to a single customer.

- Low Rejection Rate

- Out of 25,000 delivered components, only 7 were rejected. That's a rejection rate of just 0.00028% or fewer than 280 PPM.

- Annual Production

- We manufacture over 250,000 components and spare parts per annum.

- Rigorous Quality Standards

- We have consistently met the quality standards set by the customer. We have held top quality supplier status for over 20 years.

Looking for work?

Summit Engineering are always hiring skilled welders, machinists, fabricators and fettlers.

Explore open positions